| EC225 Super Puma H225 | |

|---|---|

A Spanish Maritime Safety Agency EC225 at A Coruña Airport | |

| General information | |

| Type | Passenger transport helicopter |

| National origin | Multinational |

| Manufacturer | Eurocopter Airbus Helicopters |

| Primary user | CHC Helicopter[1] |

| Number built | 170+(as of 2016[update])[2] |

| History | |

| Manufactured | 1999–present |

| Introduction date | December 2004 |

| First flight | 27 November 2000 |

| Developed from | Eurocopter AS332 Super Puma |

| Variants | Eurocopter EC725 |

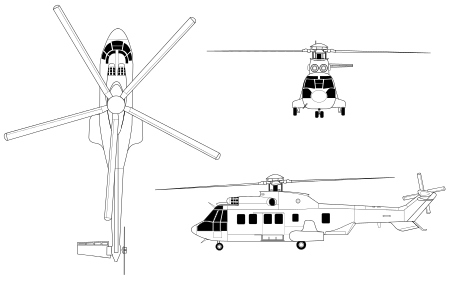

The Airbus Helicopters H225 (formerly Eurocopter EC225 Super Puma) is a long-range passenger transport helicopter developed by Eurocopter as the next generation of the civilian Super Puma family. It is a twin-engined aircraft and can carry up to 24 passengers along with two crew and a cabin attendant, dependent on customer configuration. The helicopter is marketed for offshore support and VIP passenger transport duties, as well as public service missions.

The civil-orientated EC225 has a military counterpart, which was originally designated as the Eurocopter EC725; it was rebranded in 2015 as the H225M. In 2015, the EC225 was formally renamed to the H225, in line with Eurocopter's corporate rebranding as Airbus Helicopters.[3]

Development

[edit]In the aftermath of the 1973 oil crisis, oil and gas companies began exploration and extraction activities farther offshore, thus creating a long-term need for more capable rotary aircraft.[4] The development of the EC225, an enlarged variant of the AS332 Super Puma, was announced by Eurocopter in June 1998. The principal differences of the EC225 from the preceding AS332 are the adoption of Spheriflex rotor technology and new Turbomeca Makila 2A turboshaft engines, along with a redesigned main gearbox to accommodate the rotor and engine changes, and the addition of an integrated flight display system; these changes resulted in higher speeds and passenger comfort, as well as greater flight safety and reduced operating costs.[5]

On 27 November 2000, the first prototype performed its maiden flight. In July 2004, the type received its airworthiness certification from the European Aviation Safety Agency.[5] In December 2015, the H225, a new designation used for the EC225, received certification from the Interstate Aviation Committee of the Commonwealth of Independent States; this made the H225 the first foreign heavy-lift helicopter to become certified in Russia.[6]

In February 2014, Airbus Helicopters announced at Heli-Expo 2014 the development of an improved variant, the EC225e. The EC225e features numerous changes including new avionics systems, such as the TCAS II collision avoidance system, an automatic identification system, and a specialized rig-approach system; it was also intended to feature an improved Turbomeca Makila 2B engine to increase the EC225e's maximum takeoff weight by 550 kg, and an additional fuel tank in the rear baggage compartment to extend its range to 300 nautical miles with up to ten passengers on board. Some, but not all, modifications can be retrofitted onto existing EC225s.[7][8] In the same announcement, in February 2014, Lease Corporation International said that they had placed a $645 million order for 15 EC225e (along with 6 Airbus Helicopters EC175) helicopters as the launch customer.[9] In February 2016, the Makila 2B engine was dropped from the EC225e as a cost reduction measure, development of the other structural and avionics aspects is proceeding.[10]

In 2015, Airbus Helicopters announced at the Paris Air Show that it had begun development of a clean-sheet successor to the EC225, initially designated Airbus Helicopters X6,[11] but development was stopped in early 2018. The EC225's production line is projected to continue manufacturing activity until at least 2030.[12]

Design

[edit]

The EC225 is based on the Eurocopter AS332L2 Super Puma, improving upon the design with a five-blade main rotor incorporating a new airfoil shape to reduce vibration and noise levels.[5] The blades of the rotors feature a composite spar and parabolic blade tips; they can also be equipped with an anti-icing system to enable the aircraft to operate within very cold climates. The helicopter is powered by two Turbomeca Makila 2A1 turboshaft engines mounted over the cabin; these engines are capable of providing 14 per cent more engine power and feature a redundant dual-channel full authority digital engine control (FADEC) system for high reliability, a further backup system is present in the event of both FADEC systems failing.[5][13] The FADEC system ensures that engine power is always kept within the limits of the gearbox.[13] Many of the mechanical components, particularly of the engines, were designed to be modular to ease maintenance, and composite materials were used where possible to reduce the aircraft's weight.[5][13]

A key safety feature of the aircraft's main gear box (MGB) is an emergency oil spraying sub-system present in the lubrication system; this is designed to exceed the JAR 29 Standard's requirements of a 30-minute running time in the event of the loss of MGB oil pressure, and has demonstrated up to 50-minute running time. The engine also incorporates a "blade shedding" system to ensure engine integrity during an overspeed instance.[5] Energy absorbent self-sealing fuel tanks are contained in the aircraft's sponsons, along with other equipment such as downward-facing illumination and navigation lighting fixtures.[13] The transmission can accommodate more power than the maximum output of the engines;[13] however two aircraft were lost in 2012 due to the cracking of the bevel gear shaft, a gearbox component.[14] In response, the design of the transmission was modified in 2013, and the onboard health and usage monitoring system (HUMS) was upgraded to provide real-time monitoring of the bevel gear shaft against the threat of crack formation.[14]

In terms of cockpit equipment and avionics, the EC225 is equipped with a full glass cockpit with active-matrix liquid crystal displays; these include four 6-inch by 8-inch multi-functional displays as the predominant instrumentation for key flight information, two 4-inch by 5-inch monitors for displaying aircraft parameters, and a 3-inch screen for backup.[13] The advanced helicopter cockpit and avionics system is described as serving to reduce pilot and crew workload, being used to display flight management and sub-systems information and is complete with a four-axis digital autopilot.[5] During a typical flight, the pilot programs the route into the aircraft and then monitors it, as opposed to direct continuous control of the flight; the need for paper charts has been eliminated by these systems.[13] Under autopilot, the automatic flight control system acts to prevent pilot actions from exceeding the established flight envelope; the EC225 remains flyable with all automatic systems disabled.[13] From initiating the startup sequence to being ready to takeoff only takes three minutes.[13]

There are currently a total of four principal configurations designed by Airbus Helicopters for the EC225. The passenger transport version has a crash-worthy seating arrangement for up to 19 passengers with a high-density seating arrangement accommodating up to 28 passengers available to be fitted.[13] The VIP transport version has a large lounge with seating for up to 12 passengers and a cabin attendant. The emergency medical services (EMS) configuration has medical units for six stretchers and four seats for medical workers. The search and rescue (SAR) configuration allows space for search and rescue equipment with an operator seat, hoistman seat and up to eight rescue seats and three stretchers.[15] While a single pilot is capable of controlling the aircraft under visual meteorical conditions, two pilots are used in a typical crew complement and, dependent on role, a cabin attendant or flight engineer may also be present.[13]

Operational history

[edit]

In January 2005, Algeria became the first country to use the EC225 when the Algerian Ministerial Air Liaisons Group (GLAM) took delivery of a single helicopter for VIP transport duties.[16]

In 2009, the AirKnight consortium offered the EC225 in competition against the Sikorsky S-92 offered by the Soteria Search and Rescue consortium for the United Kingdom's Search and Rescue – Helicopter (SAR-H) program to replace the RAF Search and Rescue Force's Westland Sea King fleet.[17] In 2010, Soteria was awarded the contract;[18] however, in 2011 the contract was halted as Soteria had access to confidential information.[19] In 2013, the Department for Transport awarded Bristow Group the SAR-H contract, operating a mix of Sikorsky S-92 and AgustaWestland AW189 instead.[20]

By 2011, CHC Helicopter had the largest operational fleet of EC225s, the type comprising a fifth of the firm's total rotorcraft by 2015.[1][21] CHC principally use the type for serving the offshore oil and gas industries, as well as search and rescue missions.[21] Another milestone was reached in 2011 when Eurocopter delivered the 100th production EC225 to Bristow Group.[22] In March 2013, leasing company Milestone Aviation Group placed a record order for 30 EC225s.[23][24]

Due to its popularity in offshore passenger transport, the EC225 is also commonly used as an offshore Search and Rescue aircraft, with operators based in Norway, the UK and Australia. In this role, aircraft are typically equipped with a Dual Rescue Hoist, FLIR camera, high-powered searchlights and an advanced autopilot with autohover capability.[25] The EC225 has also been used as an aerial firefighting platform, it can be equipped with a Simplex Aerospace-developed water cannon for dealing with fires in built-up urban areas, both Japan and South Korea operate several aircraft adapted in this manner.[26][27]

Following the 22 October 2012 crash, the major North Sea Super Puma operators, CHC Helicopter, Bond Offshore Helicopters and Bristow Helicopters decided to ground all AS332 and EC225 Super Puma helicopters. On 25 October 2012 it was announced that the problem was suspected to relate to the main gearbox vertical shaft; the AS 332 L1 and L2 versions of the Super Puma could be refitted with an older design, allowing them to resume flying. On 8 November 2012 some Super Pumas of Bond Offshore Helicopters returned to flight.[28][29][30] The EC225 grounding continued into 2013, following the validation of new safety measures by the EASA, the type was progressively returned to service following modifications.[31][32] By mid-2015, all 49 EC225s operating in the North Sea fleets in the UK had been retrofitted with a redesigned bevel wheel vertical shaft to avoid any recurrence.[33]

In March 2015, the Japan Coast Guard accepted delivery of its fifth and final EC225; outfitted for performing search and rescue missions, they shall also be used for security enforcement, territorial sea enforcement/monitoring and disaster relief operations.[34]

The EC225 was a candidate for the Norwegian All Weather Search and Rescue Helicopter (NAWSARH) to replace the Westland Sea King Mk.43B of the Royal Norwegian Air Force in 2015;[35] other candidates were the AgustaWestland AW101, Bell Boeing V-22 Osprey, NHIndustries NH90 and Sikorsky S-92.[36] By 9 July 2013, only the AW101 and the EC225 remained as contenders; in December 2013, the AW101 was selected instead.[37][38]

On 2 June 2016, following the crash of an H225 in Norway which revealed a potential safety issue with the main rotor assembly, the EASA issued an emergency airworthiness directive that grounded the H225 fleet;[39] by July 2016, 80 per cent of the worldwide fleet had been grounded as a result, while some operators such as the French military continued to operate its fleet.[40] In October 2016, the grounding order by the EASA was lifted; some countries, including the United Kingdom and Norway, chose to maintain operational restrictions for the type.[41] Norwegian operator Statoil, who had contracted the CHC H225 which crashed, maintained it will not return to using the helicopter even if restrictions are lifted. The company has instead relied on the Sikorsky S-92 to meet its needs since the crash.[42] By December 2016, three separate lawsuits were filed by separate H225 operators, claiming that the type had been sold in a defective state due to the flaw being "inherent".[43]

Variants

[edit]- EC225 LP

- An improved variant of the AS332 L2.

- EC225 Firefighting

- EC225 fitted with internal tanks for water bombing

- EC225 SAR

- EC225 with FLIR, dual electric winches for all-weather search, rescue operations.

- EC225e

- A version with the newer Turbomeca Makila 2B turboshaft engine.[44]

Operators

[edit]

The EC225 Super Puma is used for offshore drilling, corporate companies, law enforcement and governments.

The 34th Transport Aviation Division (People's Liberation Army Air Force) also flies EC225s.[45]

Military operators

[edit]

- Hungarian Air Force (16 on order)[49]

Civilian operators

[edit]

- Air Greenland (2 on order)[61]

- Icelandic Coast Guard — received 2 H225's in 2019 and 1 in 2021.[62][63]

- Tokyo Fire Department (2 on order)[64]

- Ministry of Internal Affairs (21 on order), deliveries started in December 2018.[69][70]

Accidents and incidents

[edit]

- 18 February 2009: G-REDU, an EC225 LP operated by Bond Offshore Helicopters. During a night visual approach to the ETAP platform, the helicopter descended and impacted the surface of the sea. The crew's perception of the helicopter's position and orientation relative to the platform during the final approach was erroneous. All 18 people on board survived the controlled flight into terrain (water).[75]

- 10 May 2012: G-REDW, an EC225 LP, carried out a controlled ditching following indications of a failure of the main gearbox (MGB) lubrication system and a subsequent failure indication warning on the emergency lubrication system. An investigation by the Air Accidents Investigation Branch (AAIB) identified a 360° circumferential crack in the bevel gear vertical shaft in the main gearbox, in the vicinity of a manufacturing weld, causing disengagement of the drive to both mechanical oil pumps.[76]

- 22 October 2012: G-CHCN, an EC225 LP of CHC Scotia, ditched in the North Sea 32 miles south west of Shetland whilst en route from Aberdeen to the West Phoenix drilling rig. All 19 on board were rescued. A special bulletin issued by the Air Accidents Investigation Branch (AAIB) said the main and standby oil pumps were not working; a 360-degree crack found on the bevel gear vertical shaft of the gearbox had prevented the oil pump gears from being driven. A worldwide grounding of the type was initiated in response.[31] In both of the 2012 incidents, although the main gearbox lubrication system had failed, the backup system was working correctly but displaying an erroneous warning light, due to an incorrect specification of a pressure switch, which led to the helicopters being ditched.[77]

- 29 April 2016: LN-OJF, an EC225 LP of CHC Helikopter Service, crashed at an islet near Turøy in the Bergen archipelago, en route to Bergen Airport, Flesland, from the Gullfaks B platform in the North Sea. The helicopter was carrying 11 passengers and 2 crew members; everyone on board died. Eyewitnesses reported that the main rotor separated from the hull immediately before the crash. Due to the crash, all commercial flights by EC225 helicopters, excluding search and rescue flights, were grounded by both Norwegian and British civil aviation authorities.[78][79][80] The subsequent investigation concluded that a gear in the main rotor gearbox had failed due to a fatigue crack that had propagated under-surface, escaping detection. As a result of the incident the German Defence Ministry had also decided to ground 3 AS532 Helicopter in government use which were manufactured by the same company.[81]

- 18 January 2023: an EC225 carrying the Minister of Internal Affairs of Ukraine, Denys Monastyrsky, his deputy Yevhen Yenin and state secretary Yurii Lubkovych, crashed at a kindergarten in Brovary, a suburb of Kyiv, Ukraine. The crash killed 14 people, including Monastyrsky, Yenin and Lubkovych; a child was also among the fatalities, while 25 others were injured.[82]

Specifications (EC 225)

[edit]

| External videos | |

|---|---|

Data from Airbus Helicopters[83]

General characteristics

- Crew: 2 (commander + co-pilot)

- Capacity: 24 passengers + 1 cabin attendant

- Length: 19.5 m (64 ft 0 in)

- Height: 4.97 m (16 ft 4 in)

- Empty weight: 5,256 kg (11,587 lb)

- Gross weight: 11,000 kg (24,251 lb)

- Max takeoff weight: 11,200 kg (24,692 lb)

- Powerplant: 2 × Turbomeca Makila 2A1 turboshaft engines, 1,776 kW (2,382 hp) each

- Main rotor diameter: 16.2 m (53 ft 2 in)

- Main rotor area: 206.15 m2 (2,219.0 sq ft)

Performance

- Maximum speed: 275.5 km/h (171.2 mph, 148.8 kn)

- Cruise speed: 260.5 km/h (161.9 mph, 140.7 kn)

- Never exceed speed: 324 km/h (201 mph, 175 kn)

- Range: 857 km (533 mi, 463 nmi)

- Ferry range: 985 km (612 mi, 532 nmi)

- Service ceiling: 5,900 m (19,400 ft)

- Rate of climb: 8.7 m/s (1,710 ft/min)

See also

[edit]Related development

Aircraft of comparable role, configuration, and era

Related lists

References

[edit]- ^ a b CHC Helicopter (2010). "CHC Fleet". Archived from the original on 13 February 2013. Retrieved 11 January 2011.

- ^ "Airbus Helicopter infographic". Archived from the original on 14 March 2017. Retrieved 2 June 2016.

- ^ "VIDEO: Meet the H Generation." Airbus Helicopters, 3 March 2015.

- ^ Kay, Marcia Hillary. "40 Years Retrospective: It's Been a Wild Ride" Rotor & Wing, August 2007. Accessed: 8 June 2014. Archived 8 June 2014 at the Wayback Machine on 8 June 2014.

- ^ a b c d e f g "The EC 225 is Certified IFR by the European Airworthiness Security Agency." Eurocopter, 29 July 2004.

- ^ "Airbus Helicopters' H225 receives Russian certification ." Vertical Magazine, 3 December 2015.

- ^ Osborne, Tony. "Airbus Launches Refreshed EC225." Aviation Week, 26 February 2014.

- ^ Trimble, Stephen. "HELI-EXPO: Airbus adds power, range and automation to EC225." Flight International, 26 February 2014.

- ^ ""LCI orders 6 Airbus Helicopters EC175s; becomes an EC225e launch customer, ordering 15."" (PDF). Archived from the original (PDF) on 1 March 2014.

- ^ Perry, Dominic. "Airbus Helicopters drops new engine from H225 upgrade." Flight International, 5 February 2016.

- ^ "Airbus starts development of new X6 heavy helicopter." Reuters, 16 June 2015.

- ^ Perry, Dominic. "Paris: Airbus Helicopters launches X6 concept phase." Flight International, 16 June 2015.

- ^ a b c d e f g h i j k "Flight Test: Eurocopter EC225 – Puma repowered." Flight International, 22 September 2009.

- ^ a b Osborne, Tony. "Certification for EC225 Interim Fixes Imminent." Aviation Week, 19 June 2013.

- ^ "EC225 – Brochure." Airbus Helicopters, Retrieved: 24 May 2015.

- ^ "Algerian EC225." Flight International, 11 January 2005.

- ^ Osborne, Tony (11 March 2009). "SAR-H bidders announce helicopter types". Shephard Group. Archived from the original on 25 July 2009.

- ^ "Team Soteria wins UK's SAR-H deal with proven S-92." Flight International, 9 February 2010.

- ^ "Search and rescue helicopter bid process is halted". BBC News. 8 February 2011. Retrieved 8 February 2011.

- ^ "Written statement to Parliament. Search and rescue helicopters". Department for Transport. 26 March 2013. Retrieved 26 March 2013.

- ^ a b "CHC becomes first operator to reach 100,000 flight hours with H225." Airbus Helicopters, 29 July 2015.

- ^ "Eurocopter delivers the 100th EC225 to Bristow Group." Archived 15 March 2012 at the Wayback Machine Eurocopter, 12 July 2011.

- ^ "New Super Puma helicopters to Serve Angola's oil and gas sector." offshoreenergytoday.com, 27 February 2014.

- ^ "Milestone Aviation Group increases Eurocopter EC225 order to 30 aircraft and announces order for five EC175s." Archived 8 December 2015 at the Wayback Machine Milestone Aviation Group, 6 March 2013.

- ^ "Shell launches landmark search and rescue service in Broome". Shell.

- ^ "Simplex Aerospace Receives Order for High Rise Firefighting System for Japan." Archived 5 March 2016 at the Wayback Machine simplex.aero, 12 August 2013.

- ^ "South Korea Firefighting, Rescue Services Provider National 119, Benefits From Rapid, On-Site EC225 Support From Helicopter MRO Company Heli-One." Business Wire, 2 March 2015.

- ^ Perry, Dominic (25 October 2012). "Gearbox component failure to blame for latest EC225 ditching". Flight Global.

- ^ Learmont, David (26 October 2012). "Operators return some Super Pumas to work as EASA widens safety ruling". Flight Global.

- ^ Step change (27 October 2012). "Q&A Fact Sheet on latest ditching incident". Archived from the original on 22 February 2013.

- ^ a b "SonAir Welcomes EC225 Pair Back Into Service." Aviation Today, 31 July 2013.

- ^ Calderwood, Dave. "EC225 helicopters return to service." Archived 24 May 2015 at the Wayback Machine international-pilot.com, 14 October 2013.

- ^ Earl, Ed. "Three brand-new Super Pumas join North Sea fleet." Archived 24 May 2015 at the Wayback Machine Evening Express, 2 May 2015.

- ^ Waldron, Greg. "Japan Coast Guard takes delivery of fifth EC225." Flightglobal.com, 2 March 2015.

- ^ "The NAWSARH Project". Royal Norwegian Ministry of Justice and the Police. Archived from the original on 7 June 2011. Retrieved 6 June 2009.

- ^ Per Erlien Dalløkken (7 May 2009). "De fem kandidatene". Teknisk Ukeblad (in Norwegian). Archived from the original on 11 May 2009. Retrieved 6 June 2009.

- ^ Kai de la Cruz (9 July 2013). "To av de mulige Sea King-erstatterne er vraket". Tu.no. Retrieved 30 April 2016.

- ^ Ministry of Justice and Public Security (27 January 2015). "NAWSARH". Government.no. Retrieved 30 April 2016.

- ^ Dubious, Thierry. "EASA Grounds Airbus AS332 L2/EC225 LP Fleet." AIN Online, 3 June 2016.

- ^ Perry, Dominic. "More bad news for Airbus Helicopters Super Puma family." Flight International, 20 July 2016.

- ^ Osborne, Tony. "EASA Lifts Airbus H225 Grounding, But Not UK, Norway." Aviation Week, 7 October 2016.

- ^ "Statoil drops Airbus Super Puma helicopters for good". Reuters. 6 December 2016. Retrieved 6 December 2016.

- ^ Johnson, Oliver. "Airbus Helicopters sued by three companies over H225 situation." Vertical, 9 December 2016.

- ^ "Airbus Helicopters Presses Ahead With New Models". ainonline.com. 11 April 2014. Archived from the original on 13 April 2014. Retrieved 12 April 2014.

- ^ "Orbats - Scramble". www.scramble.nl. Archived from the original on 8 September 2017. Retrieved 2 September 2020.

- ^ "La Prefectura Naval Argentina adquiere el primer helicóptero EC225 Súper Puma". infodefensa.com.

- ^ defenceWeb (21 September 2016). "Botswana military receives Super Puma helicopter".

- ^ a b c d e f "World Air Forces 2019". Flightglobal Insight. 2019. Retrieved 5 January 2019.

- ^ "Hungary orders 16 H225M multi-role helicopters | Airbus". 28 October 2021.

- ^ "Japan Defense Agency received first EC225 in VIP configuration for the Japanese Emperor's Royal Flight Service". eurocopter.com. Archived from the original on 9 April 2013. Retrieved 20 March 2013.

- ^ "Eurocopter succeeds with EC 225 in open Japanese competition". eurocopter.com. Archived from the original on 9 April 2013. Retrieved 20 March 2013.

- ^ Dominguez, Gabriel (21 June 2017). "Japan Coast Guard orders three additional H225 helicopters". IHS Jane's 360. London. Archived from the original on 22 June 2017. Retrieved 22 June 2017.

- ^ "Japan Coast Guard orders additional H225 chopper". Navy Recognition. 25 April 2018. Archived from the original on 25 April 2018. Retrieved 3 May 2018.

- ^ "Orbats". www.scramble.nl. Retrieved 11 September 2024.

- ^ "Oman's Royal EC-225LP". smallairforces.com. 3 May 2011. Retrieved 17 January 2014.

- ^ Auto, Hermes (29 March 2021). "RSAF starts taking delivery of improved H225M helicopters to replace Super Pumas". The Straits Times.

- ^ "Перші два вертольоти Airbus надійшли на службу до Нацгвардії та ДСНС". ukrinform.ua (in Ukrainian). 21 December 2018. Archived from the original on 28 January 2021. Retrieved 19 January 2021.

- ^ "Eurocopter delivers fourth EC225 to China for offshore SAR". helihub.com. 7 August 2011. Retrieved 20 March 2013.

- ^ "Eurocopter and COHC sign a Contract for the Supply of long range EC225 Helicopters". eurocopter.com. Archived from the original on 29 October 2013. Retrieved 20 March 2013.

- ^ "Guangdong Public Security Bureau will have the world "most advanced" helicopter". informationtimes.dayoo. Archived from the original on 20 July 2011. Retrieved 20 March 2013.

- ^ "Air Greenland orders two EC225 helicopters for use in all-weather missions". eurocopter.com. Retrieved 20 March 2013.

- ^ Jennings, Gareth (1 April 2019). "Iceland coastguard receives new helos". Jane's 360. London. Archived from the original on 1 April 2019. Retrieved 1 April 2019.

- ^ "TF-GRO". Landhelgisgæsla Íslands (in Icelandic). Retrieved 25 March 2022.

- ^ "Tokyo Fire Department orders second EC225". helihub.com. 17 July 2012. Retrieved 20 March 2013.

- ^ "MHS Aviation fleet". mhsaviation.com. Archived from the original on 11 February 2013. Retrieved 20 March 2013.

- ^ "CHC Helicopter fleet". no.chc.ca. Archived from the original on 1 April 2014. Retrieved 2 May 2016.

- ^ "Norway: Aviation authority grounds all EC225 helicopters after crash near Bergen". offshoreenergytoday.com. 29 April 2016. Archived from the original on 2 May 2016. Retrieved 2 May 2016.

- ^ "Fomento adjudica a Eurocopter el súper Helimer". elcorreogallego.es. Archived from the original on 27 September 2011. Retrieved 20 March 2013.

- ^ "Україна та Airbus helicopters підписали Угоду про постачання 55 гелікоптерів для потреб ДСНС, Національної поліції, Нацгвардії та Прикордонної служби" [Ukraine and Airbus Helicopters signed a deal on delivery of 55 helicopters for the State Emergency Service, National Police, National Guard, and Border Guard Service] (in Ukrainian). Кабінет міністрів України. 14 July 2018. Retrieved 14 July 2018.

- ^ "Ukraine takes delivery of first H225 helicopters". 3 May 2022.

- ^ "Bond Aviation Group fleet". bondaviationgroup.com. Archived from the original on 5 October 2013. Retrieved 20 March 2013.

- ^ "Bristow Helicopters fleet". bristowgroup.com. Retrieved 20 March 2013.

- ^ "VNH South - EC-225". www.vnhs.com.vn. Retrieved 24 October 2021.

- ^ "До України прибув вже п'ятий гелікоптер H225 Super Puma" (in Ukrainian). Мілітарний. Retrieved 21 January 2023.

- ^ "Report on the accident to Eurocopter EC225 LP Super Puma, G-REDU..." AAIB.

- ^ "Aircraft Accident Report AAR 2/2014 – Eurocopter EC225 LP Super Puma, G-REDW and Eurocopter EC225 LP Super Puma, G-CHCN, 22 October 2012." Air Accidents Investigation Branch, 10 May 2012.

- ^ Air Accidents Investigation Branch (11 June 2014). "Aircraft Accident Report AAR 2/2014 — Air Accidents Investigation Branch report – GOV.UK". www.gov.uk. Retrieved 19 October 2015.

- ^ "Helikopterstyrt i Hordaland". www.aftenposten.no. 29 April 2016. Retrieved 29 April 2016.

- ^ "Helicopter crashes on Norway coast". bbc.co.uk. BBC News. 29 April 2016. Retrieved 29 April 2016.

- ^ "SAFETY DIRECTIVE No. 16/05616-1". Civil Avitation Authority Norway. Archived from the original on 3 May 2016. Retrieved 26 April 2017.

- ^ "Germany grounds Merkel's helicopter after fatal Norway crash". Reuters. 3 June 2016. Retrieved 10 April 2021.

- ^ "Ukraine crash: Ministers killed as helicopter comes down near nursery". BBC News. 18 January 2023. Archived from the original on 18 January 2023. Retrieved 18 January 2023.

- ^ "Products > EC225 specifications." Airbus Helicopters, Retrieved: 24 May 2015.